High-grade Criteria in Virgin Transformer Oil for Reliable Applications

High-grade Criteria in Virgin Transformer Oil for Reliable Applications

Blog Article

Protect the Setting With Trustworthy Transformer Oil Recycling Provider

The importance of transformer oil recycling can not be overemphasized, specifically in the context of environmental conservation. The question stays: just how can companies properly pick a recycling provider that aligns with their environmental objectives?

Significance of Transformer Oil Recycling

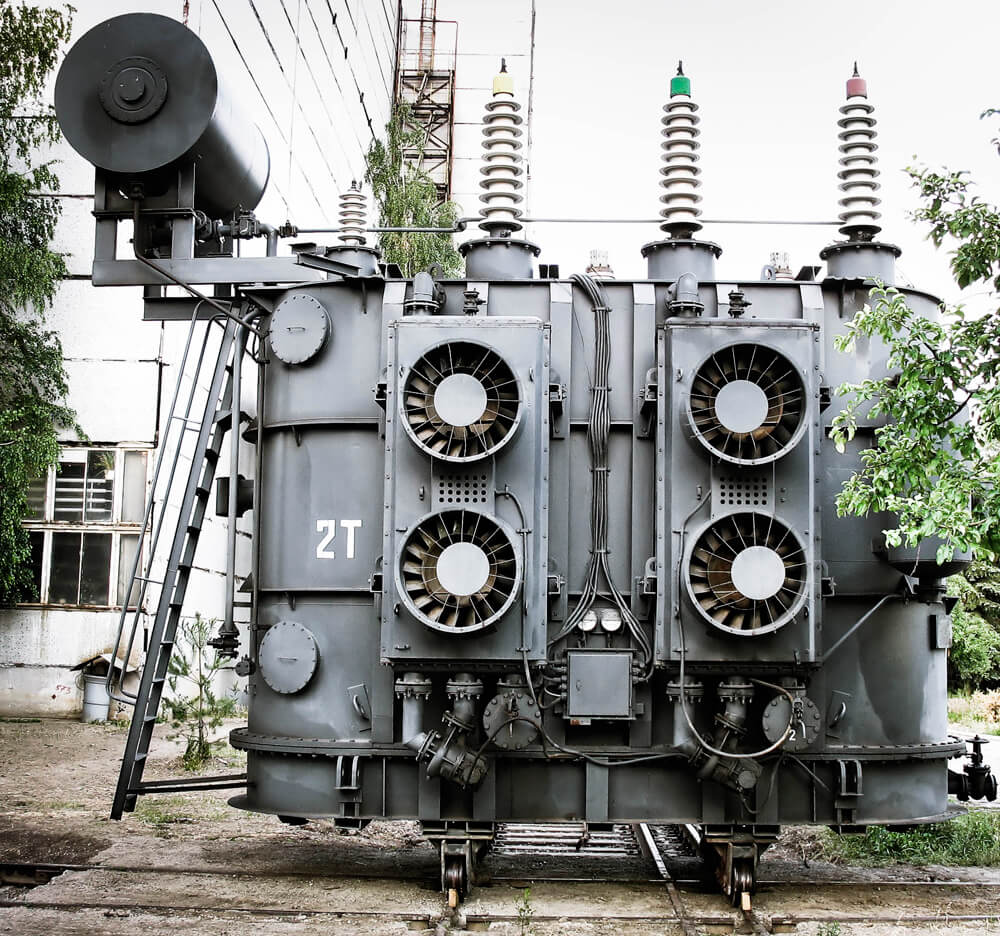

Transformer oil recycling is progressively acknowledged as a crucial practice in the management of electrical framework. Using transformer oil, important for cooling and insulating electrical transformers, leads to the accumulation of waste oil that requires liable handling. Reusing this oil not just conserves useful natural resources however likewise plays a crucial duty in promoting sustainability within the energy field.

In addition, transformer oil recycling can substantially lower functional expenses for utilities and services. By reusing oil, companies can reduce expenditures connected with acquiring new oil and handling waste disposal. Carrying out effective recycling programs shows a dedication to ecological stewardship and operational effectiveness, positioning business as leaders in lasting practices within the electrical industry. Generally, the importance of transformer oil recycling can not be overstated as it sustains both eco-friendly and financial goals.

Environmental Impact of Improper Disposal

The incorrect disposal of transformer oil presents considerable ecological risks that can not be overlooked. Transformer oil typically consists of harmful materials, consisting of polychlorinated biphenyls (PCBs), which can infect soil and water resources if launched into the atmosphere. When incorrectly discarded, these harmful chemicals can leach into groundwater, posing serious health threats to local environments and neighborhoods.

Furthermore, transformer oil can interrupt aquatic environments when it gets in bodies of water, resulting in detrimental impacts on fish and other wildlife. The oil creates a movie on the water surface area, restricting oxygen exchange and hindering photosynthesis in marine plants. Moreover, the persistence of these pollutants in the setting can bring about bioaccumulation in the food cycle, impacting not just wildlife but additionally human health with the intake of contaminated fish and water.

Along with chemical contamination, incorrect disposal can cause physical dangers, such as oil spills, which call for expensive removal initiatives. The long-term effects of ignoring proper disposal techniques extend past environmental degradation, as neighborhoods may deal with economic difficulties as a result of decreased all-natural resources and boosted health care prices. Virgin Transformer Oil. Addressing these dangers is crucial for lasting environmental stewardship

Advantages of Professional Recycling Solutions

Reliable management of transformer oil with professional recycling solutions offers various advantages that expand beyond simple conformity with ecological policies. Among the key advantages is the reduction of environmental threats connected with incorrect disposal. By making use of specialized recycling processes, business read what he said can lessen the threat of soil and water contamination, thus protecting environments and public wellness.

In addition, specialist recycling solutions contribute considerably to source preservation. Transformer oil can be improved and recycled, lessening the demand for brand-new oil manufacturing. This not only saves all-natural more helpful hints resources however additionally reduces energy intake and greenhouse gas exhausts related to oil extraction and refining.

Moreover, involving with specialist solutions boosts functional effectiveness. Services can improve their waste management procedures, guaranteeing that transformer oil is handled securely and sensibly. This can cause set you back savings in waste disposal and potential responsibilities associated to ecological damages.

The Recycling Process Described

Using expert recycling solutions not only aids in lowering ecological risks and preserving sources but additionally entails an organized approach to the reusing procedure itself - Virgin Transformer Oil. The recycling of transformer oil starts with the collection of utilized oil, which is commonly infected with different impurities, including dirt, water, and metal bits

When accumulated, the oil undergoes a comprehensive analysis to determine its problem and the essential therapies needed for effective recycling. Next, the oil undergoes filtration and purification processes, which might consist of vacuum cleaner purification, clay therapy, and degasification. These techniques effectively remove pollutants, bring back the oil to a usable state.

After filtration, the recycled transformer oil is examined to ensure it meets sector requirements and requirements. By using these thorough actions, expert recycling services ensure that transformer oil is recovered effectively, lowering waste and advertising lasting methods.

Picking the Right Recycling Service Provider

Picking the best recycling service provider for transformer oil is a crucial decision that can considerably impact both environmental sustainability and operational effectiveness. When assessing potential solution carriers, it is essential to consider their certifications and conformity with environmental regulations. A credible recycler will certainly stick to nationwide and local requirements, guaranteeing that the recycling procedure reduces environmental injury.

In addition, take a look at the company's experience and proficiency in handling transformer oil. An established business with a tested track document will have the essential modern technologies and approaches to reuse oil effectively, preserving its high quality and reducing waste. Transparency in their processes and determination to share data regarding their recycling results can also indicate a credible partner.

Expense is an important element; however, it should not be the sole component. Assess the overall worth provided by the service provider, including their service dependability, consumer assistance, and the possibility for partnership in future sustainability efforts. Lastly, seek reviews or situation research studies from previous clients to gauge their complete satisfaction. visit this website By very carefully considering these aspects, companies can pick a recycling supplier that straightens with their ecological goals while making sure responsible and efficient administration of transformer oil waste.

Verdict

In conclusion, the importance of reputable transformer oil recycling services can not be overstated. Inevitably, the fostering of effective transformer oil reusing practices plays a crucial duty in cultivating a sustainable round economy and shielding vital environments.

The use of transformer oil, necessary for cooling and insulating electric transformers, leads to the accumulation of waste oil that demands liable handling.By recycling transformer oil, companies can minimize their reliance on brand-new oil production, which is typically resource-intensive and environmentally taxing. By reusing oil, organizations can minimize expenditures associated with acquiring brand-new oil and managing waste disposal.Efficient management of transformer oil via expert recycling solutions provides many benefits that extend past simple compliance with ecological policies. Transformer oil can be refined and recycled, diminishing the demand for brand-new oil manufacturing.

Report this page